The Vacuum Oven by Jeiotech is built to meet the rigorous demands of laboratories in South Africa. With precise temperature control up to 250 °C, this advanced oven supports a wide range of applications. It delivers excellent temperature uniformity, with just ±1.5 °C fluctuation at 100 °C, ensuring consistent, reproducible results—making it a reliable choice for scientific research.

Structural and Functional Features

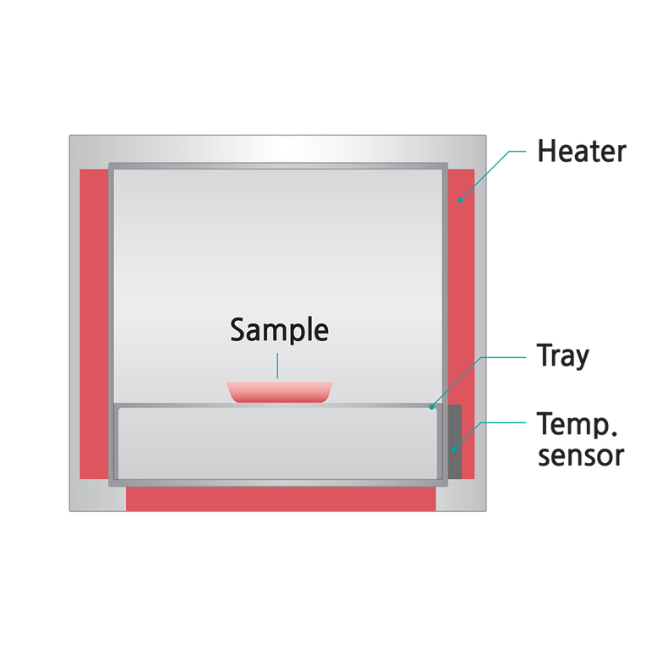

This vacuum oven includes three-point temperature calibration for improved accuracy across the operating range. The shelves, made from stainless steel and aluminum, resist corrosion and allow for easy cleaning. Furthermore, the oven includes safety circuits that guard against overcurrent and overheating.

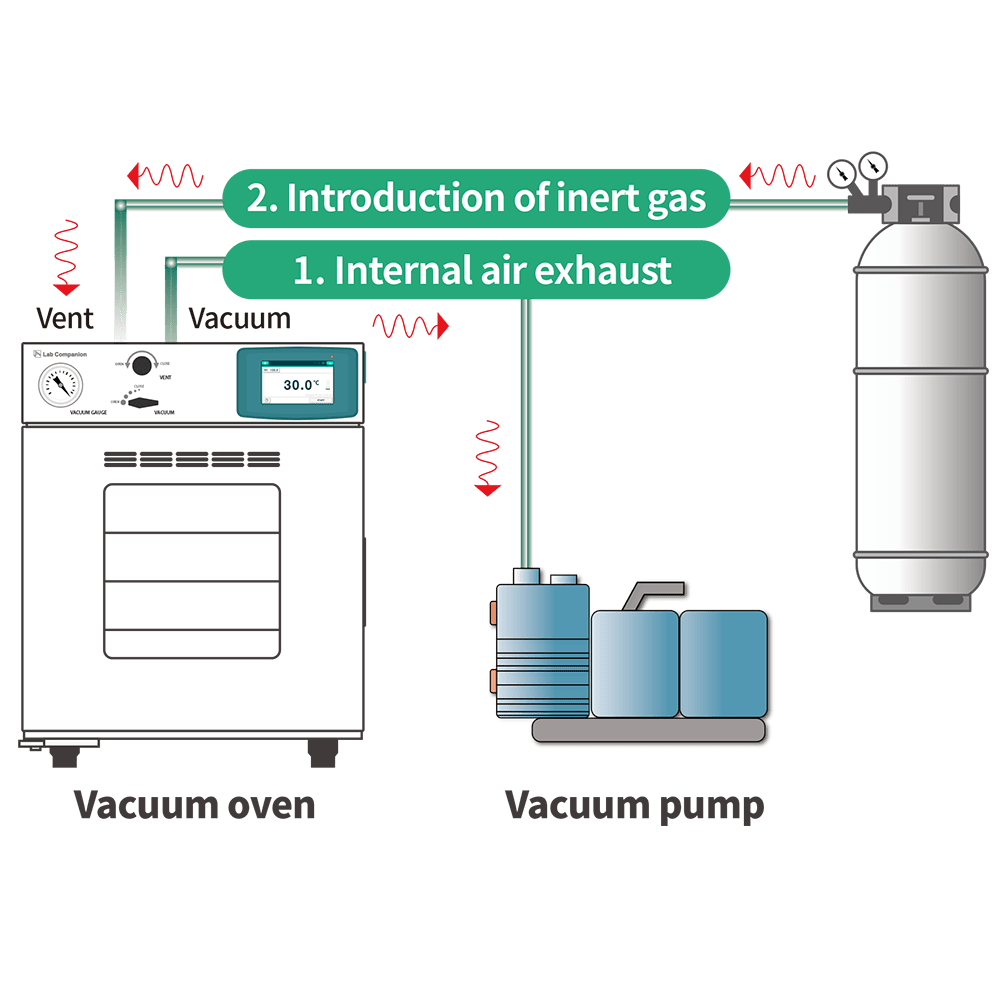

To improve usability, the vacuum and release lines are separated, and the top-mounted display saves floor space. For laboratories working with high-reactivity substances, an optional Viton gasket is available.

Convenience Features

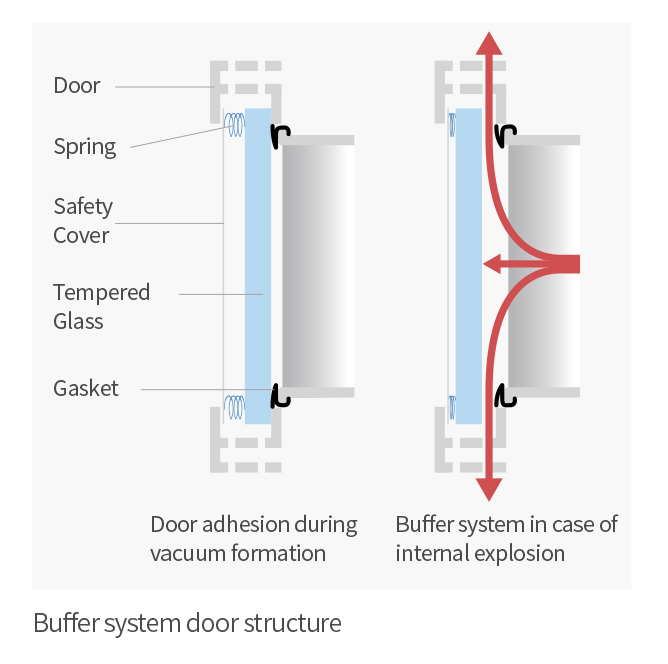

Once a vacuum forms, toughened glass seals tightly against the gasket, providing reliable, long-term performance. The oven also integrates with building management systems (BMS) via a communication port, enabling temperature monitoring at a facility level.

Additionally, the LC Connected mobile system allows for remote operation. The large LCD screen improves visibility, while the wait on/off timer enables flexible scheduling up to 99 hours and 59 minutes.

Outstanding Safety Mechanisms

Safety remains a core part of this oven’s design. The door structure includes a buffer system that releases internal pressure through upper and lower ventilation holes. In case of glass breakage, a polycarbonate safety cover helps protect users.

Additionally, the oven logs up to 36 critical events, including door openings and system errors. Over-temperature protection, deviation alarms, and industry-leading fail-safes give users confidence in both routine and sensitive operations.

If you’re exploring more products or alternatives, check out our guide: Forced, Natural Convection, and Vacuum Ovens – How to Choose? on our Insights page. At Apex Scientific, we provide high-quality equipment designed for modern laboratories.